-

Thor Compact Handheld Laser Welding Machine

Iimbonakalo:

1. Umatshini wokuwelda uyafumaneka nge-1.5kW, 2kW kunye ne-3kW laser diodes

2. Umthungo we-welding ococekileyo kunye nokuphazamiseka okuncinci, okugqibeleleyo kwi-0.5-5mm ubukhulu be-welding

3. Izihlanganisi ozikhethelayo zokuwelda i-laser ye-autogenous, i-laser-filling laser welding, kunye ne-laser brazing.

4. Ukusebenzisana neerobhothi zemizi-mveliso ezithi kunye zizise amandla kunye nokuguquguquka kwezinto ezivelisa ubunzima kunye nobukhulu obukhulu.

5. Ifaka isicelo kumashishini ombane azinzileyo, imveliso yemoto, i-sheet metal processing, umbane, uloliwe njl.

6. Indawo echaphazelekayo yokushisa incinci ngexesha le-welding, engayi kuvelisa i-deformation, i-blackening, okanye ilandelelanisa kwi-workpiece, kunye nobunzulu be-welding ngokwaneleyo, i-welding iqinile, kwaye i-melting ininzi. Iziphumo ze-welding ziya kuba zicocekile kwaye zicoceke ngaphandle kwe-deformation okanye ukudakumba.

7. Imveliso isebenzisa inkqubo yokulawula ukuzimela, i-high threshold optics, izitshixo ezininzi zokhuseleko, i-coolers yamanzi, kunye noyilo lwe-ergonomic. Ezi mpawu ziphucula kakhulu iziphumo ze-welding, zandisa ukhuseleko kunye nokuzinza kwezixhobo, ukuphucula induduzo yabasebenzisi, ukunciphisa ukudinwa komsebenzi, kunye nokwandisa iiyure zokusebenza.

Isixhobo se-laser esiphathwa ngesandla sisetyenziswe ngokubanzi kwi-welding applications yensimbi engenasici, i-aluminium, ubhedu kunye nezinye isinyithi. Ukusetyenziswa kwivalve engunxantathu, abenzi boluvo, oomatshini, izikhongozeli zentsimbi, izifakelo zemibhobho yentsimbi kunye nezinye iindawo zokuwelda iphepha, indlela yokuwelda i-laser yindlela eguqukayo yokusebenza.

-

KELEI Copana Robotic Welding System

Inkqubo yeCopana sisisombululo serobhothi samva nje se-KELEI esiquka:

1. Itekhnoloji yokusika

2. Umgangatho ophezulu we-laser

3. Uguqulo olusebenzayo lombane-optic

4. Isicelo se-welding esisodwa

5. Umsebenzisi osebenza lula

6. Ukufakwa kweekhowudi ngokulula

7. Imilo yendawo ye-laser ehlengahlengiswayo

-

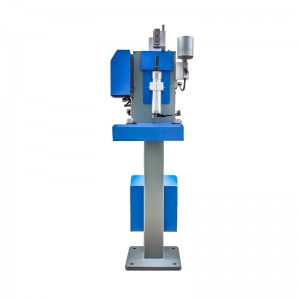

KELEI Thor Handheld Laser Welding Machine

Iimbonakalo:

1. Umatshini wokuwelda uyafumaneka nge-1.5kW, 2kW kunye ne-3kW laser diodes

2. Umthungo we-welding ococekileyo kunye nokuphazamiseka okuncinci, okugqibeleleyo kwi-0.5-5mm ubukhulu be-welding

3. Izihlanganisi ozikhethelayo zokuwelda i-laser ye-autogenous, i-laser-filling laser welding, kunye ne-laser brazing.

4. Ukusebenzisana neerobhothi zemizi-mveliso ezithi kunye zizise amandla kunye nokuguquguquka kwezinto ezivelisa ubunzima kunye nobukhulu obukhulu.

5. Ifaka isicelo kumashishini ombane azinzileyo, imveliso yemoto, i-sheet metal processing, umbane, uloliwe njl.

6. Indawo echaphazelekayo yokushisa incinci ngexesha le-welding, engayi kuvelisa i-deformation, i-blackening, okanye ilandelelanisa kwi-workpiece, kunye nobunzulu be-welding ngokwaneleyo, i-welding iqinile, kwaye i-melting ininzi. Iziphumo ze-welding ziya kuba zicocekile kwaye zicoceke ngaphandle kwe-deformation okanye ukudakumba.

7. Imveliso isebenzisa inkqubo yokulawula ukuzimela, i-high threshold optics, izitshixo ezininzi zokhuseleko, i-coolers yamanzi, kunye noyilo lwe-ergonomic. Ezi mpawu ziphucula kakhulu iziphumo ze-welding, zandisa ukhuseleko kunye nokuzinza kwezixhobo, ukuphucula induduzo yabasebenzisi, ukunciphisa ukudinwa komsebenzi, kunye nokwandisa iiyure zokusebenza.

Isixhobo se-laser esiphathwa ngesandla sisetyenziswe ngokubanzi kwi-welding applications yensimbi engenasici, i-aluminium, ubhedu kunye nezinye isinyithi. Ukusetyenziswa kwivalve engunxantathu, abenzi boluvo, oomatshini, izikhongozeli zentsimbi, izifakelo zemibhobho yentsimbi kunye nezinye iindawo zokuwelda iphepha, indlela yokuwelda i-laser yindlela eguqukayo yokusebenza.

-

KELEI Handheld Laser Welding Torch

Uphawu:

1. KELEI imveliso ezimeleyo ye-R&D enike amalungelo awodwa omenzi wechiza ali-14

2. Ngaphezulu kwe-40% yezinga lokuguqulwa kombane

3. Ukusetyenziswa kwiintlobo ngeentlobo zemathiriyeli

4. Ububanzi be-welding obulungiswayo obulungele abasebenzisi

5. Iyahambelana ne-fiber yeemitha ezili-10 ezinokunceda umgama omde we-welding

6. Amanani eendlela zokusebenza ziyakwazi ukulungelelanisa nayiphi na i-angle kunye nobunzima

7. Izitshixo zokhuseleko ezininzi zokhuseleko lokusebenza

-

Isincedisi seWelding: KLPZ-O2 Nozzle

Umbhobho okhethiweyo we-KELEI Thor umatshini we-laser welding welding

-

Isincedisi seWelding: KLPZ-Y2 Nozzle

Umbhobho okhethiweyo we-KELEI Thor umatshini we-laser welding welding

I-Welding Nozzle yokuwelda ngesandla kwelaser

ICopper yokuqala / Ubushushu kunye nokumelana ne-slag / Gqibezela ukhetho lobungakananiUkusebenza okukhulu kunye noKuhlala ixesha elide

Umatshini ococekileyo / Ubushushu kunye nokumelana ne-slag

Ubunzima obuphezulu, ukumelana nobushushu obuphezulu kunye ne-conductivity ephezulu

Umphezulu uyagqithiswa ukunciphisa ukunamathela kwe-slag ephaphazelayo, ukugqibezela okugudileyo ukuqinisekisa ukuzinza kwamandla aphumayo.

-

KELEI Robot-sebenzisa iLaser Welding Torch

Intshayelelo yeMveliso:

I-KELEI Laser igxile kwimpumelelo kwiitekhnoloji eziphambili eziphuhliswe kubuchwephesha bethu obusele bukhokele kwishishini. Iminyaka yophando olunzima lwenze inkqubo yethu yeCopana Robotic Welding. Ngamava avela kubuchule bethu beprojekthi etyebileyo, amava oshishino, i-R&D kunye nesakhono sokwenza, sigxile ekukhuthazeni ukuzenzekelayo kunye nezixhobo ezikrelekrele zokuvelisa ezikumgangatho ophezulu, eziya kunceda abathengi bethu bafezekise ngakumbi kwaye babize kancinci.

I-laser yenziwa yi-laser kwaye ihanjiswa yindlela yangaphandle yangaphandle. Emva kokugxila kwisibuko sokugxila kwi-welding joint, yenza kwi-weld phakathi kwezinto eziza kucutshungulwa. Ngoncedo lwegesi ekhuselayo (ukuthintela izinto ezivela kwi-oxidized), izixhobo zixutywe ukuba zenze i-pool ethile etyhidiweyo, ukuze kufezekiswe injongo ye-welding.

-

KELEI Robotic Laser Cutting Head

Le mveliso ithatha inzuzo yokuguquguquka kunye nokuhamba ngokukhawuleza kweerobhothi zoshishino kunye nokudibanisa kunye nezixhobo zokulandelelana kunye nezixhobo zokuhambisa i-optical transmission. Imveliso isebenzisa itekhnoloji yefiber laser ukuphuhlisa iiparameters zenkqubo ezahlukeneyo zobunzima bepleyiti ezahlukeneyo ngelixa isenza ipleyiti yokusika i-multi-directional ukuhlangabezana neemfuno zemveliso. Ukuqinisekisa ukufakwa okugudileyo kunye namava omsebenzisi, inkampani yethu ikwabonelela ngeenkonzo zokucoca kwi-intanethi/ngaphandle kwe-intanethi ukusombulula amaxhala akho ngexesha lokusetyenziswa kakhulu.

-

Ukusika iLaser yeRobhothi

1. Ukulawula ngokulula, ngenxa yenqanaba eliphezulu lobukrelekrele benkqubo

2. Ukuguquguquka okuphezulu kunye nokuguquguquka kwezinto zokusebenza

3. Iziphumo zokusika ezihambelanayo kunye nomgangatho wemveliso

4. Isantya esiphezulu, ukuchaneka, kunye nokuthembeka

-

KELEI Thunderbolt Isicoci seTotshi

Uphawu:

1. Ukubonelela ngococi oluchanekileyo nolusebenzayo kuninzi lweerobhothi zokuwelda

2. Ukusika ucingo olukhulu naphantsi kweendawo zokusebenza ezinzima

3. Ulwelo lwe-Anti-splash lunokunciphisa umphumo we-welding splash kunye nokunciphisa imfuno yokugcinwa

4. Yehlisa i-welding slag enceda ukuthoba imfuno yolondolozo kunye nokwandisa ixesha lokugcinwa

5. Iimpawu zokubeka kunye nokusika ucingo apho i-wire cutter inokusebenza ngokuchanekileyo kwaye ingenasiphako

6. Qinisekisa ukuba itotshi ikwimeko entle ngokwandisa okuchazwe ngokuchanekileyo kunye ne-flash-over.

7. Amacandelo okucoca atyunjiweyo anokucoca ngokufanelekileyo ioli, amanzi kunye nokungcola kwisiphaluka segesi, esiphucula ubomi benkonzo yezixhobo ngokubanzi.

8. Ukusetyenziswa kwee-reamers ezikhethekileyo kunye neengcingo zokusika ezinobunzima obuphezulu, kunye nokuqina okuqinileyo, kunye nobuchwepheshe bokutywinwa kwe-oyile yokutywinwa kunye nokusika ucingo oluzenzekelayo, kuphucula kakhulu ukuqina kunye nomgangatho wokucheba izixhobo.

-

KELEI Box Welding Station

Uphawu:

1. I-welding ngokuzenzekelayo kwinqanaba elinye kunye nokuphazamiseka okuncinci kunye ne-post-processing, ehambelana nobukhulu be-0.5-5mm

2. Iiparamitha ezibekwe kwangaphambili zinokugqiba ngokukhawuleza ibhokisi ye-welding ukuya kwi-800mm ububanzi

3. Ilungele ukuvelisa iimveliso ezisemgangathweni

4. Isebenza kumashishini ombane ozinzileyo, i-sheet metal processing, umbane, umzila kaloliwe njl

5. Iinketho ezahlukeneyo zokuphuma kwelaser ukuya kuthi ga kwi-2kW

-

KELEI Aeolus Handheld Laser Coca Machine

Uphawu:

1. Umatshini wokucoca uyafumaneka nge-1kW, 1.5kW kunye ne-2kW laser diode

2. kunye neentloko zokucoca i-KELEI, inkqubo yokucoca i-5-10x isebenza ngakumbi xa kuthelekiswa neemveliso ze-congeneric

3. Ikulungele kakuhle ukusetyenzwa kobukhulu obukhulu kunye neemveliso eziveliswe ngobuninzi

4. Ifaka isicelo kumashishini ombane azinzileyo, imveliso yemoto, i sheet metal processing, umbane, uloliwe njl.

5. Ukukhuselwa kwamanqanaba amaninzi + ikhabhinethi enganyangekiyo kwi-corrosion, uyilo olulodwa lokungenisa umoya, kunye nokutshatyalaliswa kokushisa okusebenzayo kwandisa ixesha lokusebenza kwemveliso yethu.

6. Iteknoloji yokucoca i-laser ye-Advanced pulse ibonelela ngokucoca okungonakalisi okungabangeli monakalo kwi-substrate. Ukucoca ngokufanelekileyo ipeyinti yomhlaba, ioli, i-rust, ifilimu ye-oxide kunye nezinye izinto ezingcolileyo eziqhelekileyo kwizinto eziphathekayo.